EZ Orbital 517A Welding System

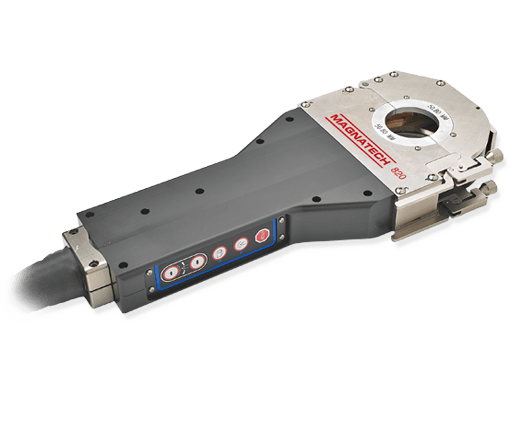

Orbital Weld Heads for Innovative Fusion Welding of Tube

Magnatech introduces an innovate solution to orbital tube welding with its modular EZ Orbital welding systems. The model 517A is a tube welding controller that integrates the operation of a standard, commercial GTAW power source with the weld head. Used with all heads of the 800 series, digital control of rotation speed regulation, ensuring perfect repeatability.

Download/View PDF Request Quote

HOW EASY IS EZ ORBITAL?

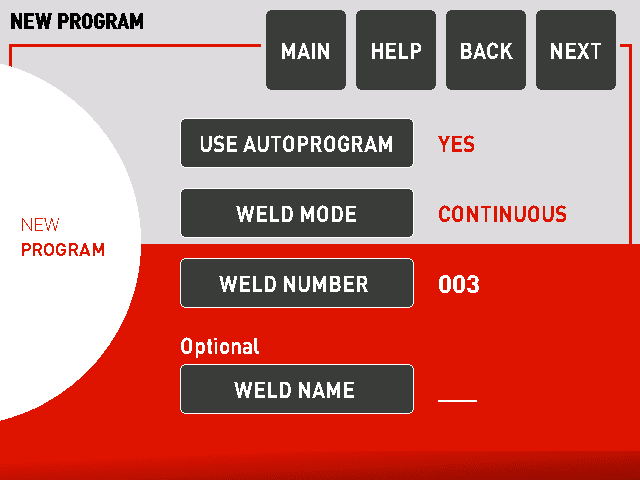

The model 517A Controller has an intuitive symbol-based touch-screen user interface. Operation

involves selecting a tube size and wall thickness and pressing the Start Weld switch on the Head.

The operator can adjust amperage by a percentage override to accommodate tube lot variation.

1 From Start Up Display

EZ ORBITAL WELDING SYSTEM

Features

- Full color, touch screen operation

- Intuitive symbol-based operation

- Autoprogram generation - entry of the tube OD and wall thickness creates optimal weld patterns

- Simple % adjustment of welding parameters

- Real time head temperature monitoring and over temperature alert

- Visual display of welding cycle

- Diagnostic fault detention system (gas purge, weld jam. etc.)

- Software updates available by internet download via USB interface

- Compact and lightweight controller built into rugged waterproof case

Options

- Extension Cable

Messages Tab

Compatibility

| Specifications | |

|---|---|

| Length x width x height | 394 x 711 x 191 mm (15.5 x 20 x 7.5 inches”) |

| Weight | 8 kg (17.5 lbs) |

| Power supply capability | Consult factory for suitable models |

| Input power requirements | 115/230 VAC, 1 Ø, 0.5 A fuse, 50/60 Hz |

| Unites of measurement | Metric and inch (selectable) |

| Operating temperature | -18 to 50˚ C (0 to 120˚ F) |

| Storage temperature | -25 to 60˚C (-20 to 140˚ F) |

| Humidity | To 98% RH (non-condensing) |