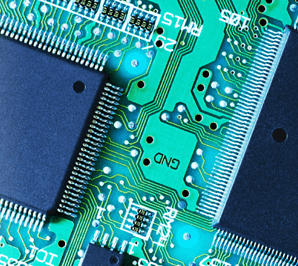

Semiconductor Industry

Orbital tube welding solutions for high purity gas delivery applications

Since the early 1980's, autogenous orbital GTAW welding has been utilized for joining the high purity gas delivery and process piping in the semiconductor and related industries.

A semiconductor fabrication facility contains miles of stainless process lines transporting the gases used in chip manufacturing. These gases may be highly toxic and highly corrosive. The high degree of weld integrity required is only achieved by orbital GTAW welding. Most semiconductor welding is done using weld Heads which fully enclose the joint, ensuring superior gas coverage and minimized any oxidation of the weld bead. Wall thickness and tube material generally allows fusion welding to be done in a single pass, without added filler wire. The introduction of the SEMI F 78-0304 standard in the early 1990's provided a comprehensive guideline for orbital GTAW use by specialist contractors.

- Magnatech orbital equipment is user-friendly - easy to program and use.

- Magnatech's 800 Series Heads incorporate all controls on the weld head for practical operation away from the power source.

- Digital technology eliminates the need for periodic weld head calibration – providing the repeatability mandated by the semiconductor welding industry.

Magnatech power sources incorporate integral weld monitoring software, which provides immediate QC data and ensures that every fusion weld is made within defined acceptance criteria limits. Let Magnatech demonstrate what set us apart in equipment ease of use, reliability, with worldwide training and service.

Orbital welding of the predominant 0.25" - 0.50" (6.3 - 12.7mm) tube sizes has become routine to meet the stringent standards in the industry. Recently, the application of orbital tube welding has expanded to the welding of non-critical, gas exhaust and environmental gas purge lines for the new 450 mm wafer processing tools, requiring orbital welding of up to 8" lines.

Applications

Challenge

Global Foundries is constructing the most advanced semiconductor-manufacturing complex in Malta, NY. Fab 8, Module 1 is the first of several foundries. A contractor, Kleeberg Mechanical Services, competing for the task of welding 2" OD process gas exhaust lines, submitted samples which were manually welded. These were rejected, as the prime contractor insisted all welding be done with orbital systems.

Solution

Kleeberg purchased an EZ Orbital System and was subsequently awarded the contract.

University Semiconductor Manufacturing Facility

Equipment Used

Challenge

Northwestern University School of Engineering is constructing a new clean room for their NUFAB advanced micro/nano fabrication research facility. It is used in research in MEMs/NEMs, nano-bio, nano/microelectronics and related areas. The contractor, Great Lakes Plumbing and Heating Company, was awarded the contract to weld both process and inert gas lines, as well as process tool tie-in lines from 1/4" to 1-1/2" OD, but were inexperienced with this application, where welds had to meet SEMI standards.

Solution

Magnatech supplied a Tubemaster 514 power source with 810 and 820 Heads. The Tubemaster automatically generates programs by selecting tube OD, wall thickness, and material. While this program produced perfect welds on other tube materials, it was found to cause a discoloration in the heat-affected zone (HAZ) with the particular tube material supplied. The Tubemaster provides the user with the capability of precisely programming each parameter. With the assistance of Magnatech's local representative, a program was created that minimized heat input, while still achieving adequate penetration, and eliminating the discoloration in the HAZ.