Offshore Oil and Gas Production

Mechanized welding solutions for offshore oil and gas production

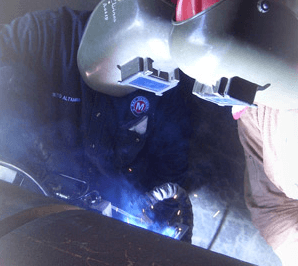

Exploration for new oil and gas fields is increasingly moving offshore. The wide range of applications, with welds often subjected to extreme environments, put a high demand on weld quality. Magnatech equipment has been used extensively for offshore pipeline welding projects using the GTAW and FCAW processes.

Many gas and oil fields contain high levels of dangerous and corrosive hydrogen sulfide and carbon dioxide. Special CRA (Corrosion Resistant Alloy) clad pipes are used to withstand corrosion, and require special welding techniques. Multi-billion dollar pipelines have been destroyed in months if the welding is not properly performed. Magnatech pipeline welding systems offer a proven solution.

Magnatech provides solutions for the welding of small diameter, heavy wall Duplex stainless steel pipes used for control of sea floor well components.

The gigantic platforms that are used for both drilling and production are constructed of large diameter tubular assemblies. Fabricators use Magnatech's Pipeliner system, with its high deposition rate FCAW process for welding of the legs, known as "jackets". The "topsides" platform equipment and process piping are welded by fabricators worldwide using Magnatech orbital welding systems.

- Specialized pipeline welding systems for offshore welding

- Proven solutions and technical expertise in welding CRA clad piping

- Magnatech provides operator training and assistance developing weld procedures worldwide.

With growing energy demand globally, the technology to extract offshore oil and gas in ever deeper waters demands the weld integrity that automated orbital welding can uniquely provide.