Pipeliner II 609

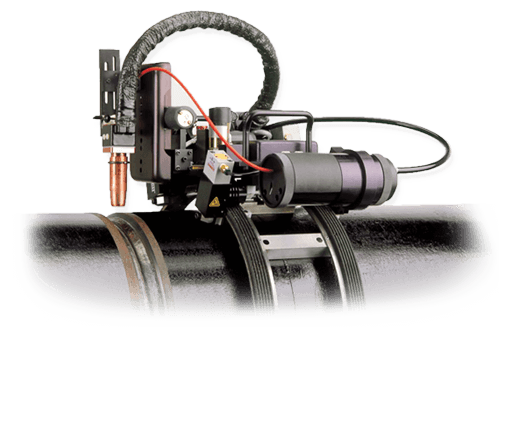

Orbital Weld Head for Multi Pass GMAW/FCAW Pipe Welding

The Magnatech Pipeliner II is designed to make pipe-to-pipe and pipe-to-fitting welds. Interchangeable guide rings mount the head on the pipe, allowing a broad workpiece size range from 168 – 1524 mm (6”– 60”) and larger.

The Pipeliner II improves productivity by increasing duty cycle, reducing repair rates, and producing welds of consistent quality.

FLX-TRACK™

In addition to welding pipework, the Pipeliner is also used for ID and OD welding on larger tanks, vessels, and ductwork.

- Flexible track allows mounting on complex curved surfaces

- Standard 2.3m (7-1/2’) Track sections bolt together for longer lengths

- Magnetic or Vacuum attachment

PIPELINER mounted on Flx-Track in 3.3m (11 ft.) diameter stainless steel duct

Features

- Full Function Capability (Torch Rotation, Filler Wire Feed, Motorized Arc Gap Control, Electronic Oscillation)

- Broad Pipe Size Range with change of single component – the Guide Ring

- Water-Cooled Torch uses standard Expendables

Messages Tab

Pipeliner II 609

| Specifications | |||||

|---|---|---|---|---|---|

| Application | Pipe size – 168 mm (6.625”) and larger |

||||

| Pipe wall thickness – unlimited | |||||

| Flx-Track™ for welding on flat and curved surfaces | |||||

| OSCILLATION MODULE (LINEAR) | |||||

| Output rating | 0 – 51 mm (2”) | ||||

| Oscillation speed | 0 – 2540 mm/min. (100 ipm) | ||||

| Oscillation dwell | 0 – 1 second. Independently adjustable at both stroke endpoints | ||||

| Cross seam adjustment | ± 25 mm (1.0”) | ||||

| OSCILLATION MODULE (PENDULAR) Allows sockets/fillet welding |

|||||

Cross seam adjustment |

± 20 degrees | ||||

| Torch vertical motion module | Stroke: 66 mm (2.625”) (motorized) |

||||

| Speed: 1520 mm/min. (60 ipm) maximum | |||||

| Tractor module | Poly-Track® propulsion (patented) | ||||

| Speed capability | 0 – 762 mm/min. (30 ipm). Higher speed motors available | ||||

| Travel direction | Switch selectable (on head) | ||||

| Wire | Wire diameter: | 0.8 – 1.6 mm (0.03 – 0.62”) | |||

| Wire feed speed: | 0.5 – 22 m/min. (20 – 866 ipm) | ||||

| Wire spool size: | 15/16 kg (25/33 lbs) | ||||

| Water-cooled torch | Amperage capability: 300 amps continuous. Uses standard torch components | ||||

| Torch adjustment capability | Torch lead/lag adjustment: | ± 15 degrees (manual) | |||

| Torch tilt adjustment: | ± 10 degrees (manual) | ||||

| Angle bracket (optional): | ± 45 degrees (manual) | ||||

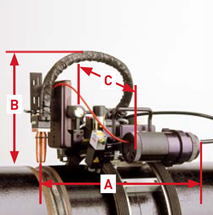

| Dimensions/weights | Axial Length A1 |

Minimum |

Overall Width |

Weight 3 |

|

|

609 WFOF | 38.7cm (15.25”) | 24.8cm (9.75”) | 30.5cm (12”) | 9.8 kgs (21.5 lbs) |

| 609 WFPP | 37.5cm (14.75”) | 24.1cm (9.50”) | 41.3cm (16.25”) | 11.6 kgs (26.5 lbs) | |

| 609 WFOH | 66.7cm (26.25”) | 26.7cm (10.5”) | 36.8cm (14.5”) | 14.4 kgs (31.75 lbs) | |

| 1 Center of oscillation stroke 2 Center of vertical stroke 3 Weight without wire spool (WFOH). Includes 1.6 kg (3.5 lb.) of Torch Cable Weight (Partial) |

|||||

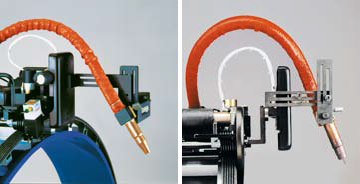

Left -Optional Pendular Oscillator positioned for fillet welds

Right Optional Torch Angle Bracket for fillet and socket weld applications

Left -Optional Pendular Oscillator positioned for fillet welds

Right Optional Torch Angle Bracket for fillet and socket weld applications