Tubemaster 514

Accurate and programmable power source for orbital weld heads

The model 514 brings the benefits of true digital technology to the orbital welding customer: unparalleled accuracy, repeatability, and reliability. Digital technology forever eliminates the need for periodic weld head calibration – rotation speed remains accurate regardless of head wear, and heads can be interchanged without time-consuming calibration. Software upgrades can be sent by e-mail attachments. The model 514 is “Internet ready�? for future enhancements such as web-based diagnostic service.

Download/View PDF Request Quote

WELD MONITORING/QC

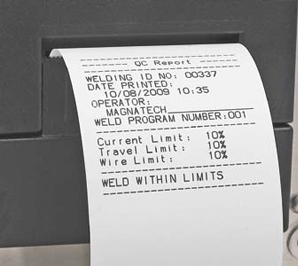

INTEGRAL WELD MONITORING SOFTWARE PROVIDES INSTANT INFORMATION ON WELD QUALITY

Features

-

WELDING CONTROLLER

- Touch screen operation

- 200 amp output

- Up to 100 levels per program

- Stores 100 weld programs internally

- Wire feed capability for wire feed Heads

- Auto Program automatically generates procedures

- Programmable “override limits�? provide supervisory control

- Weld parameter monitoring/reporting for QA/QC purpose

- Transfer programs and data to PCs using USB flash drive

- AutoTack automatically generates tack weld programs

- Head mounted membrane switches eliminate remote pendant (certain models only)

- Autoranging: 115/230 V input

- Password protection of key functions

- Built in printer allows program/QC report printout

Messages Tab

Tubemaster 514

| Specifications | ||

|---|---|---|

| Application | For use with many Magnatech weld head models (GTAW process), welding lathes, and dedicated weld systems | |

| Functions controlled | Welding current output/current pulsing, weld head rotation, Weld head wire feed speed | |

| Output power | 0 – 200 amps | |

| Input power requirements (rated load) | 115/230 VAC, 1 Ø, 4.0 KVA, 50/60 Hz autoranging (no modifications necessary) | |

| Internal memory capacity | 100 weld programs | |

| Units of measurement Metric and Inch (selectable) | Metric and Inch (selectable) | |

| Program transfer | Solid state digital media (USB flash drive/memory key) | |

| Language selection | English, Spanish, German, French, others | |

| Settable override limits | Individually scalable overrides on each function 0 – 100% | |

Maximum open circuit voltage |

80 V | |

| Water and gas flow switches | Standard. Prevent damage to equipment and workpiece | |

| Data recording/printout | Operator ID, weld ID number, program number, material, od, wall thickness, date, time, weld head model, project, drawing, programmed parameters, etc. | |

| QC-parameter monitoring/recording/printout | Monitors and records any actual deviations from preprogrammed limits recording/printout | |

| Arc start type | HF | |

| Operating/storage temperature | Operating: -18 to 50°C (0 to 120° F) Storage: -25 to 60° C (-20 to 140° F) |

|

| Humidity To 98% RH (non-condensing) | To 98% RH (non-condensing) | |

| Dimensions/weights | ||

| MODEL 514 POWER SOURCE | MODEL 904 CIRCULATOR | |

| Length | 48 cm (19�?) | 48 cm (19�?) |

| Width | 28 cm (11�?) | 28 cm (11�?) |

| Height | 32 cm (12.75�?) | 20 cm (8�?) |

| Weight | 24.5 kg (54 lbs) | 12.2 kg (27 lbs) |