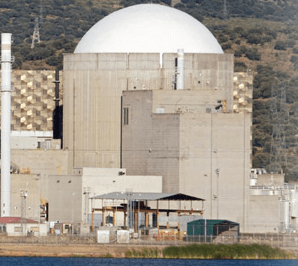

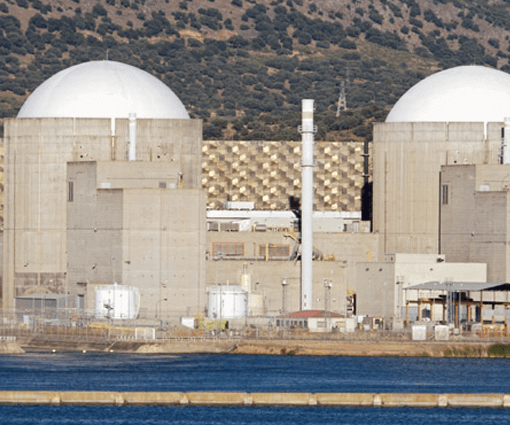

Nuclear Power Generation

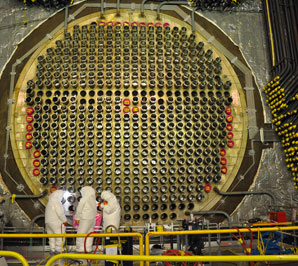

Orbital pipe and tube welding has been used in the nuclear power generation industry since the very first commercial plants were built. Fabricators and contractors demand the consistent code-quality welds and the ability to ensure that welds are made precisely within the parameters defined by the WPS/PQR. With every weld undergoing testing, the disruption to schedules for repairs and cut-outs is unacceptable. Automated orbital welding eliminates the variability of manual welding. Heat input, an important parameter for many nuclear pipe welding applications, can be precisely controlled and monitored; which is difficult to accomplish with manual welding.

Magnatech has provided both standard and modified equipment equipped with video arc monitoring for nuclear maintenance applications

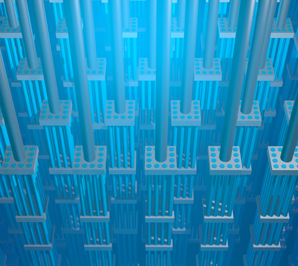

The higher duty cycle of automated orbital pipe welding reduces construction time, and allows contractors to meet the tight deadlines for work required during plant shutdowns. Our tube welding systems are used by nuclear welding contractors for small diameter instrumentation line installation.

- Long history of use for nuclear pipe welding in PWR, BWR, and CANDU design reactors

- Video Arc Monitoring Systems for nuclear pipe welding in high radiation areas

- Power sources engineered for data logging welding parameters.

Nuclear power remains a key element of electrical power supply, providing baseload capability and producing energy at a constant rate. Magnatech orbital welding systems are in routine use throughout the world by the specialized fabricators and contractors who service the nuclear power industry. We are known for our equipment reliability and ease of operation.