D-Head 420

Orbital weld heads for seamless multi-pass GTAW pipe welding connections

Orbital Weld Head for Multipass GTAW Pipe Welding

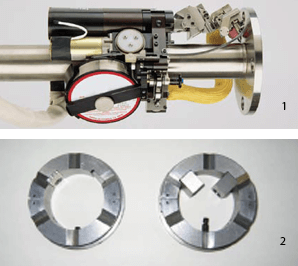

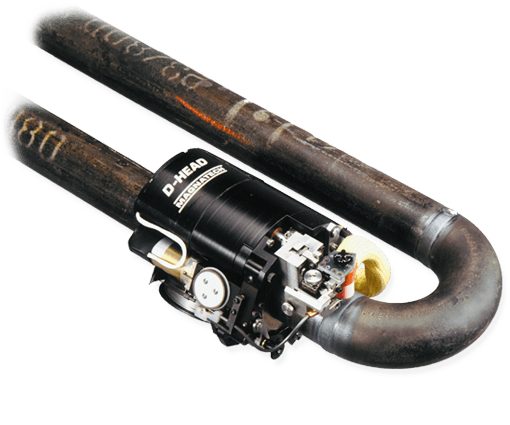

The Magnatech D Weld Head is designed to make pipe-to-pipe and pipe-to-fitting welds. It is “full function�? – with the capability of reproducing all the motions of a skilled welder. The D Weld Head is used for applications with radial and axial clearance constraints. Interchangeable guide rings provide mounting on the pipe, and allow the D Weld Head to cover a broad size range: 1�? - 14�?. The D Weld Head improves productivity by increasing duty cycle, reducing repair rates, and producing welds of consistent quality.

Download/View PDF Request Quote

Guide Rings Mount Head on Pipe. Available for all nominal pipe sizes 48 mm –

356 mm ( 11/2�? – 14�?) and Tube sizes 44 mm – 127 mm (1.75�? – 5�? O.D.)

Applications

- Fossil Power Plant Construction/Maintenance

- Steam Generation Equipment Fabrication

- Nuclear Power Plant Construction/Maintenance

- Chemical/Petrochemical Facility Construction Maintenance

- Shipyard Construction

- Gas Transmission Pipelines

- Process Piping

Features

- Full function Capability (Torch Rotation, Filler Wire Feed, Electronic Arc Gap Control, Electronic Oscillation)

- Broad size range

- Guide Rings available for standard Tube/Pipe sizes

- Waterproof Carry Case/Tool Kit standard

- Water-Cooled Torch uses standard Expendables

Guide Rings Mount Head on Pipe. Available for all nominal pipe sizes 48 mm – 356 mm ( 11/2�? – 14�?) and Tube sizes 44 mm – 127 mm (1.75�? – 5�? O.D.)

Messages Tab

L

420 D HEAD

| Specifications | ||

|---|---|---|

| Application | Multi-pass orbital GTAW pipe-to-pipe, pipe-to-fitting | |

| Cable length | 7.6 m (25’) standard. Extension cables available | |

| Pipe (tube) size range | 25 – 356 mm (1 – 14�?) | |

| Filler wire module | Wire size |

0.8, 0.9, 1.0 mm (0.03�?, 0.035�?, 0.040�?) |

| Max. speed capability | 2540 mm/min. (100 IPM) | |

| Spool size | 1 kg (2 lbs) std; 0.5 kg (1 lbs) low profile | |

| Oscillation module | Max. oscillation stroke amplitude |

16 mm (0.6725�?) |

| Max. oscillation speed | 1520 mm/min. (60 IPM) | |

| Oscillation dwell | 0 – 1 second | |

| Cross seam adjustment | ± 6.4 mm (0.25�?) | |

| Arc gap control module | 13 mm (0.5�?) stroke. Additional mechanical adjustment allows welding heavier wall pipe | |

| Torch propulsion module | 250 mm (10 IPM) maximum rotation speed | |

| Water-cooled torch | 200 A continuous capability | |

| Torch adjustment capability | Torch lead/lag adjustment |

± 15 degrees (manual) |

| Torch tilt adjustment | ± 10 degrees (manual) | |

| Power supply compatibility | Pipemaster 515, Pipemaster 516 | |

| Dimensions/weights | ||

|

Weight | 3.6 kg (8 lbs.) |

| Axial Clearance | Torch C/L to Rear Extremity: 220 mm (8.51�?) |

|

| Torch C/L to Front Extremity: 10 mm (0.41�?) | ||

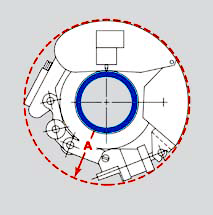

| “A�? Radial Clearance Requirement for Pipe 44.45mm (1.75�?) and larger |

64 mm (2.5�?) with Standard Spool* 51 mm (2.0�?) with Low Profile Spool* |

|

| * For pipe/tube OD’s less than 44.45mm (1.75�?), Radial Clearance Requirement increases with decreasing diameter. Contact Factory. | ||