WELD HEADS 800 SERIES

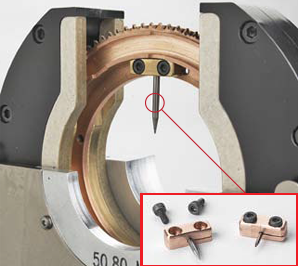

Autogenous tube welding heads for tube-to-tube and tube-to-fitting welds

Orbital Weld Heads for Fusion Welding of Tubes

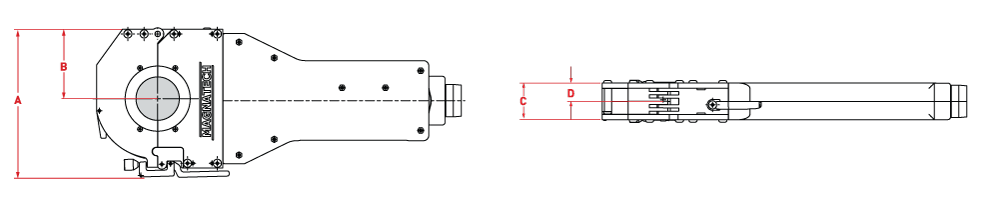

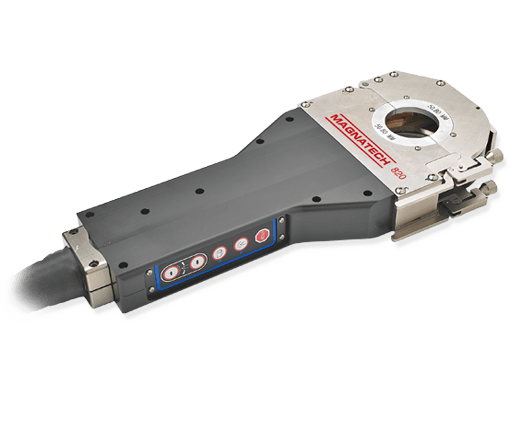

Magnatech introduces an entirely new line of easy-to-operate tools for autogenous tube welding. Five models (805, 810, 820, 830, 840, 860) with overlapping ranges cover tubes from 3 – 152 mm (0,125�? - 6�?) O.D. Magnatech’s 800 series heads make tube-to-tube and tube-to-fitting welds in less time with precision and repeatability. The double-clamping design simplifies work piece fit-up and eliminates tack welding in many cases. Collets are available for any tube and fitting size.

Digital technology forever eliminates the need for periodic weld head calibration - rotation speed remains accurate regardless of head wear and heads can be interchanged without time-consuming recalibration.

Download/View PDF Request Quote